A survey of methods and technologies for extracting rare earth elements from geothermal is discussed along with the feasibility of recovering rare earth elements from geothermal brines. Based on the findings of this study rare earth element extraction from geothermal fluids is technically possible but neither economically viable nor strategically significant at this time.

Recovery Potential Of Rare Earth Elements From Mining And Industrial Residues A Review And Cases Studies Sciencedirect

Among the 17 elements Sc and other elements have no close symbiotic relationship in natural minerals while promethium Pr is the product of natural nuclear fission in uranium ore.

/cdn.vox-cdn.com/assets/758861/Rareearthoxides.jpg)

Rare earth elements extraction. Extraction process for extraction of heavy rare earth oxides 6. Researchers from Georgia Techs School of Civil and Environmental Engineering have discovered a way to extract rare-earth elementsessential ingredients for nearly all modern electronicsfrom the ash left behind at coal-burning power plants using a non-toxic ionic liquid. Supercritical carbon dioxide has emerged in recent years as a possible extraction.

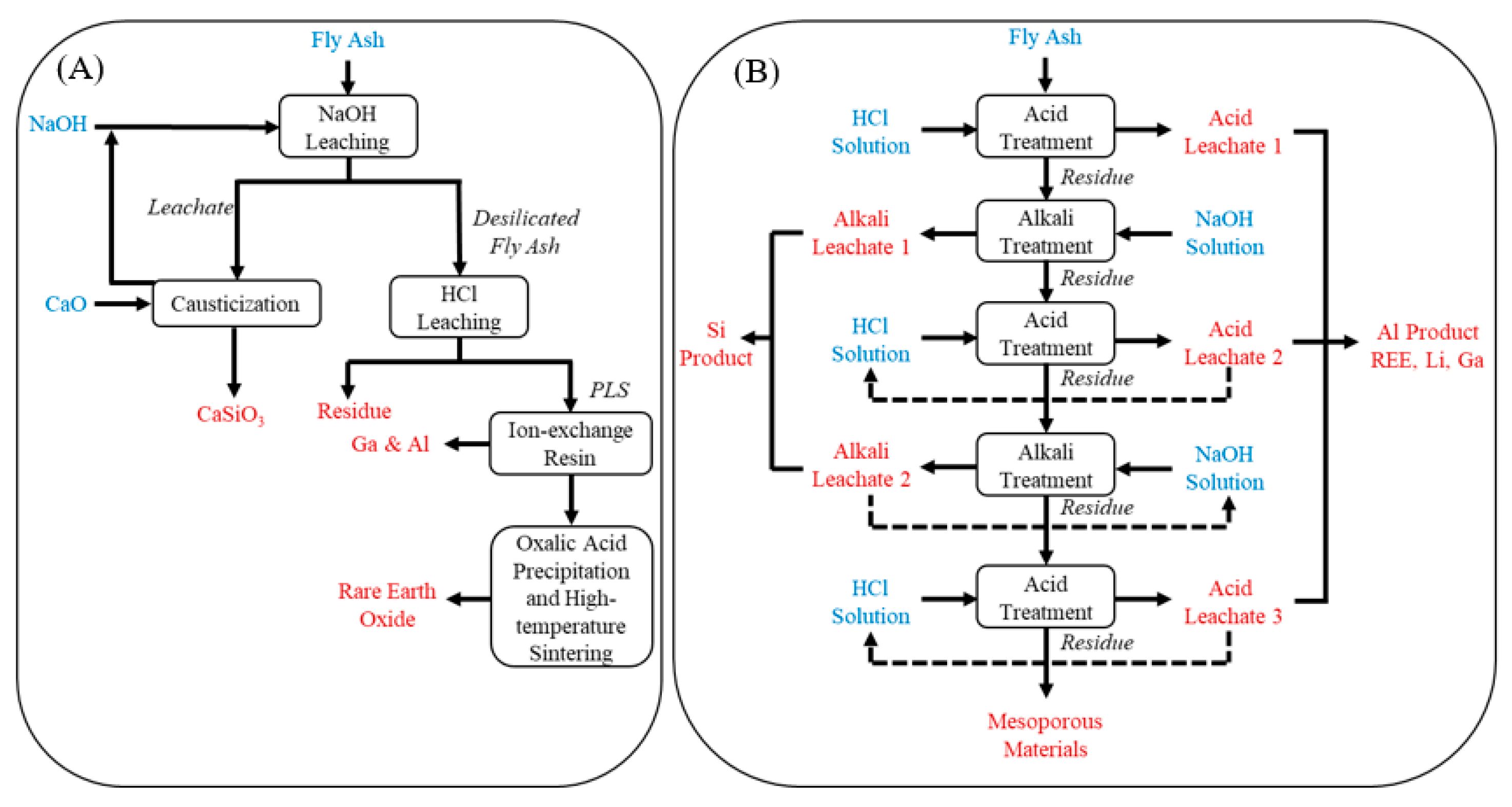

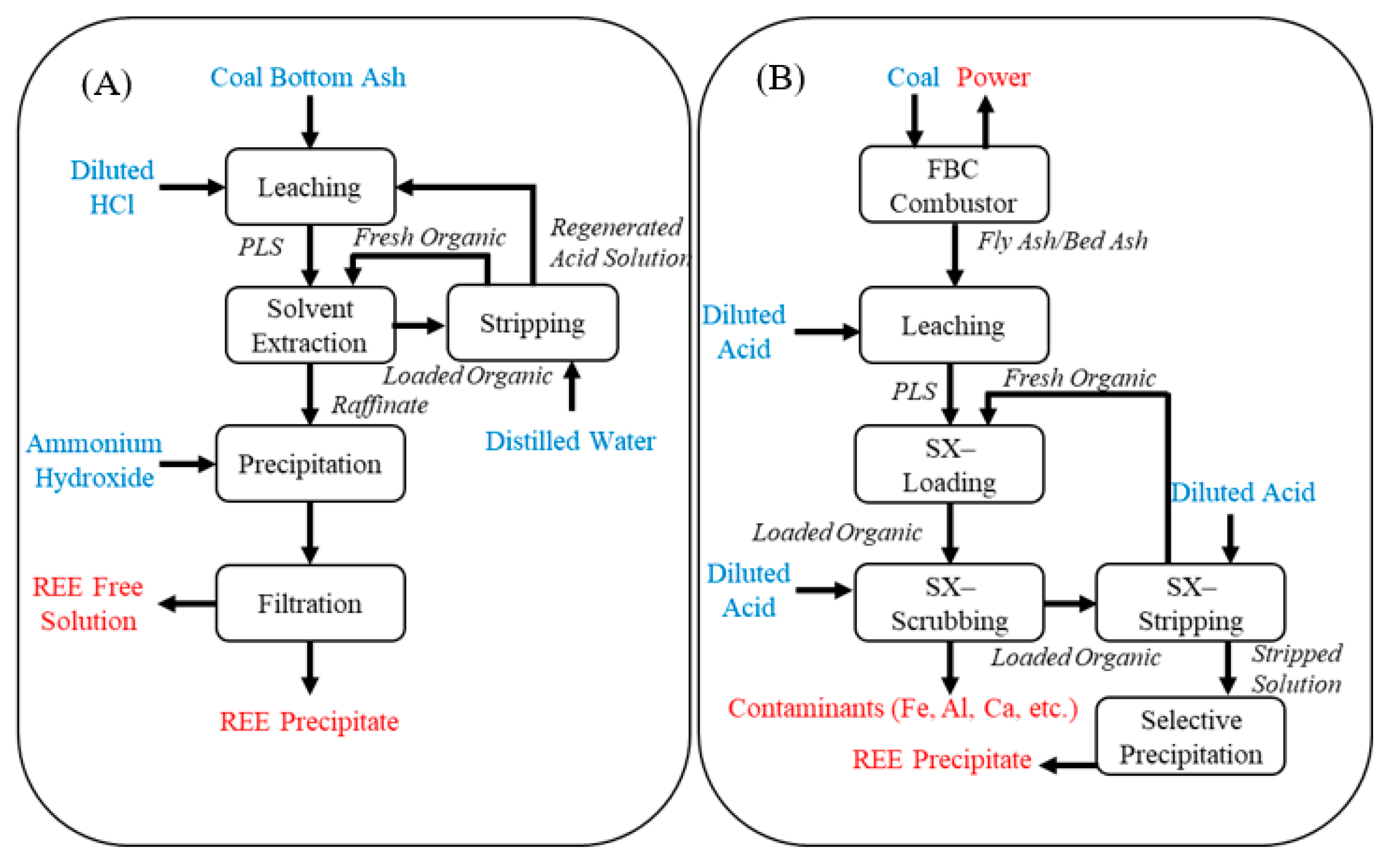

However an optimized recovery scheme is essential to create any such cost-effective and environmentally friendly process. Commonly there are three kinds of extraction technologies. A promising way of extracting value out of phosphogypsum is to recover rare earth elements.

A new extraction and separation method relies on a protein called lanmodulin LanM that first binds to all the rare earth elements in the source. Researchers at Penn State University detailed their findings in a paper published in. Lanthanum was the rare-earth element present at the highest concentration in the low-grade bauxite after the series treatments.

The overall extraction of rare earth elements from aqueous media by cation exchange extractants in their acidic form can generally be expressed as Peppard et al 1958. The bacteria bioabsorbed all the elements as they passed plucking them out of the solution and fixing them to their surface. The claimed method comprises acidic extraction of rare earth elements from phosphogypsum using sulfuric acid-nitric acid mixture solution at 32-12 ratio with concentration of 1-3 by weight and.

Extraction of individual rare earth elements from natural ores or recycled material is challenging due to the very similar chemical properties across the lanthanide series. The researchers tried a number of bio-acid mixtures of mineral and organic acids to extract six REEs yttrium cerium neodymium samarium europium and. Through the extractor picking up tetravalent cerium nitric acid and some trivalent rare-earth elements.

Extracting rare earth metals from geothermal brines is a very challenging problem due to the low concentrations of these elements and engineering challenges with traditional chemical separations methods involving packed sorbent beds or membranes that would impede large volumetric flow rates of geothermal fluids transitioning through the geothermal power plant. Demand for REE and lithium is increasing. 3 Ln 3 3 HA Ln A 3 3 H where Ln denotes any rare earth A denotes the organic anion and overscoring denotes species present in the organic phase.

Resulting extracted rare earth elements are concentrated by solvent extraction and recovered by precipitation to produce a product with 2-8 REE oxide. The fractional step method is to extract and purify rare earth elements according to their compounds different solubility in the solvent. 3 Project updatesaccomplishments Industrial participation resulting in 6 different coal waste samples with.

Rare earth elements are a critical component in many clean energy technologies. Generally the process is more complicated then expressed in Eq. Low-grade sources of rare earth elements REE for example from industrial waste typically contain many rare earth elements and other metals mixed together.

Then other metals are drained and removed. Rare earth elements REE and lithium are non-toxic metals that are considered critical materials due to their use in electronics magnets batteries and a wide variety of industrial processes important for the economy and military preparedness. Investigation of Rare Earth Element Extraction from North Dakota Coal -Related Feedstocks 11 High Yield and Economical Production of Rare Earth Elements from Coal Ash 12 Pilot-Scale Testing of An Integrated Circuit for the Extraction of Rare Earth Minerals and.

When the rare earth containing solution is passed over a resin the rare earth displaces the ion in the resin. The new method relies on a protein called lanmodulin LanM that first binds to all the rare earth elements in the source. Through the stripper where the tetravalent cerium is removed.

They immobilized a bacteria from marine algae on an assay filter and passed a solution of mixed rare earths known as lanthanides through it. A new method improves the extraction and separation of rare earth elements a group of 17 chemical elements critical for technologies such as smart phones and electric car batteries from unconventional sources. Then other metals are drained and removed.

Conventional methods to extract rare earth elements from ores generate millions of tons of toxic and acidic pollutants. Rare Earth Elements Extraction from waste mine tailings and other previously unrecoverable deposits CMC has developed and is now in a position to offer a rapid implementation of rare earth element REE extraction at old mine tailings properties located throughout the US. Ion exchange is a process in which ions in a solution are exchanged with a solid resin with an ionic charge.

Rare earth elements REEs include the 15 lanthanides from lanthanum La to lutetium Lu with atomic numbers of 5771 accompanied by chemically similar yttrium Y and scandium Sc. An optimum pH of 35 for precipitation of rare-earth elements using sodium sulphate was demonstrated where this method is recommended for the extraction of REE elements from low-grade bauxite. Through the washer where most of the trivalent rare-earth elements and nitric acid are dropped.

The fractional step method ion exchange method and solvent extraction method. A new method improves the extraction and separation of rare earth elementsa group of 17 elements critical for technologies such as smartphones and electric car batteriesfrom unconventional. The trick is using organic acids produced by bacteria to do the hard work of extracting rare earth elements REEs from phosphogypsum.

October 08 2021.

Science Of Rare Earth Elements Science History Institute

Rare Earths In The Cross Hairs Of New High Tech Arms Race Mining Com

Minerals Free Full Text A Comprehensive Review Of Rare Earth Elements Recovery From Coal Related Materials Html

Reclaiming Rare Earth Elements From End Of Life Products A Review Of The Perspectives For Urban Mining Using Hydrometallurgical Unit Operations Sciencedirect

Minerals Free Full Text A Comprehensive Review Of Rare Earth Elements Recovery From Coal Related Materials Html

Canadian Firm Secures Exclusive Rights To Purdue S Rare Earth Element Separation And Purification Technology A 4 Billion Global Market Purdue University News

Chinese Scientists Find Faster Way To Extract Rare Earths That May Also Cut Industry Pollution South China Morning Post

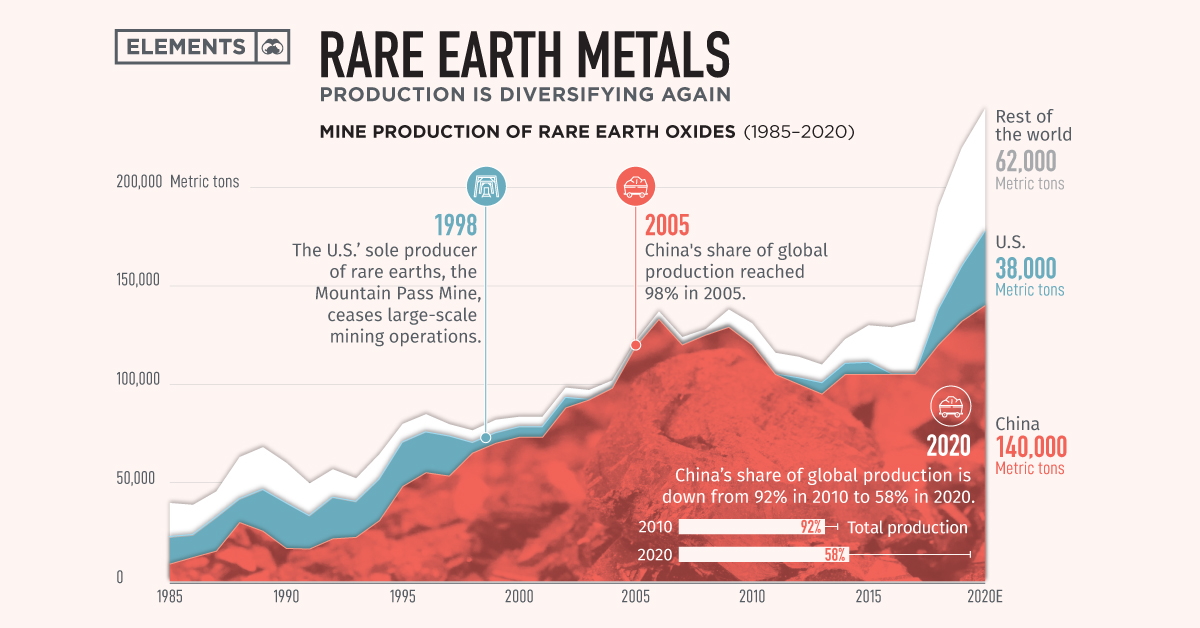

Chart Rare Earth Metals Production Is No Longer Monopolized By China

Science Of Rare Earth Elements Science History Institute

Hydrometallurgy In The Processing Of Ree Eurare Sustainable European Ree Exploitation Technologies Eurare Project

Cleaner Production Of Rare Earth Elements From Phosphorus Bearing Sulfuric Acid Solution Of Vein Deposit Monazite Sciencedirect

Review Of Rare Earth Elements Recovery From Secondary Resources For Clean Energy Technologies Grand Opportunities To Create Wealth From Waste Sciencedirect

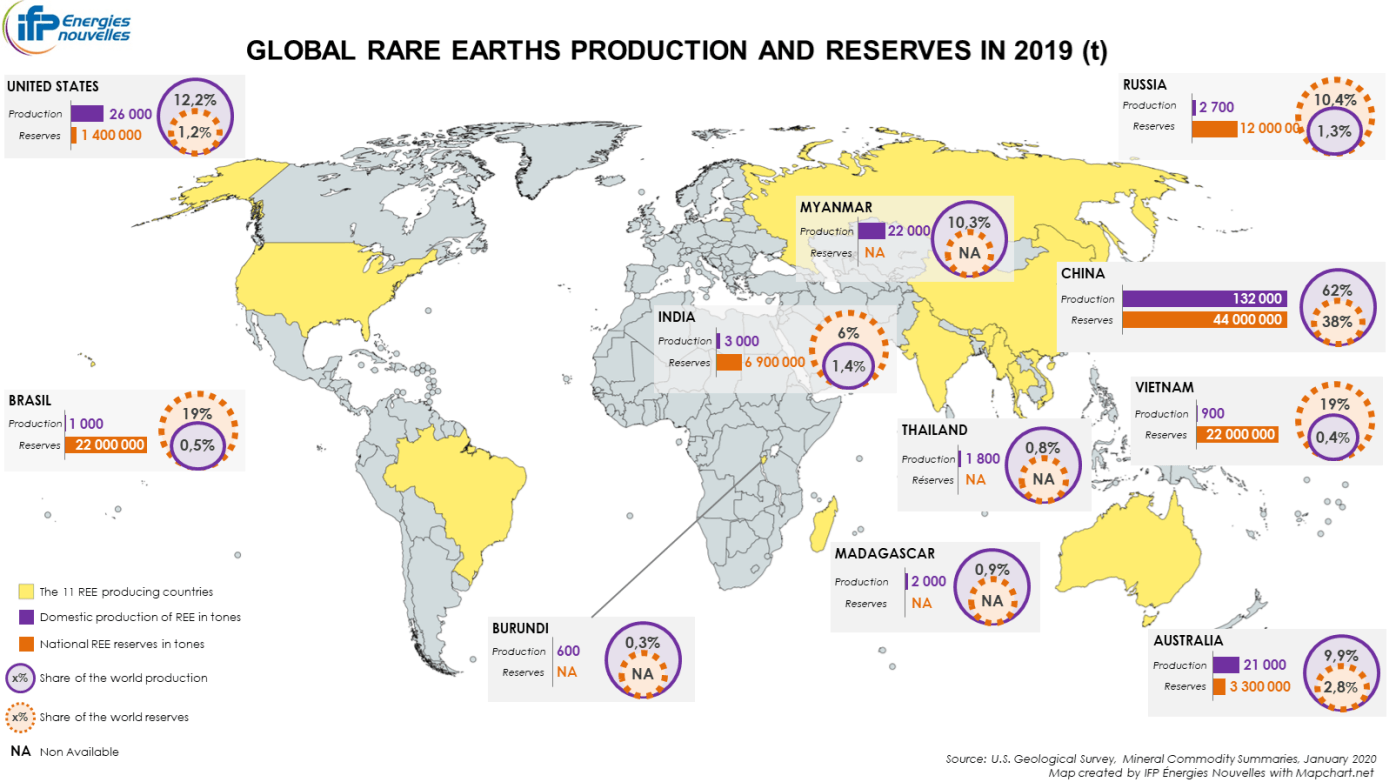

Rare Earths In The Energy Transition What Threats Are There For The Vitamins Of Modern Society Ifpen

A Visit To The Only American Mine For Rare Earth Metals The Atlantic

Rare Earth Consultant Tru Group Rare Earth Metals Consultants Engineers Rare Earth Elements Process Engineering Consultancy Ree Reo Team Tru Group Usa Canada

/cdn.vox-cdn.com/assets/758861/Rareearthoxides.jpg)

Rare Earth Elements Aren T The Secret Weapon China Thinks They Are The Verge

Toxic And Radioactive The Damage From Mining Rare Elements Environment All Topics From Climate Change To Conservation Dw 13 04 2021

Selective Extraction And Recovery Of Rare Earth Metals From Waste Fluorescent Powder Using Alkaline Roasting Leaching Process Sciencedirect

No comments:

Post a Comment